Best way to level motors and motor mounts

23 posts

• Page 2 of 3 • 1, 2, 3

Re: Best way to level motors and motor mounts

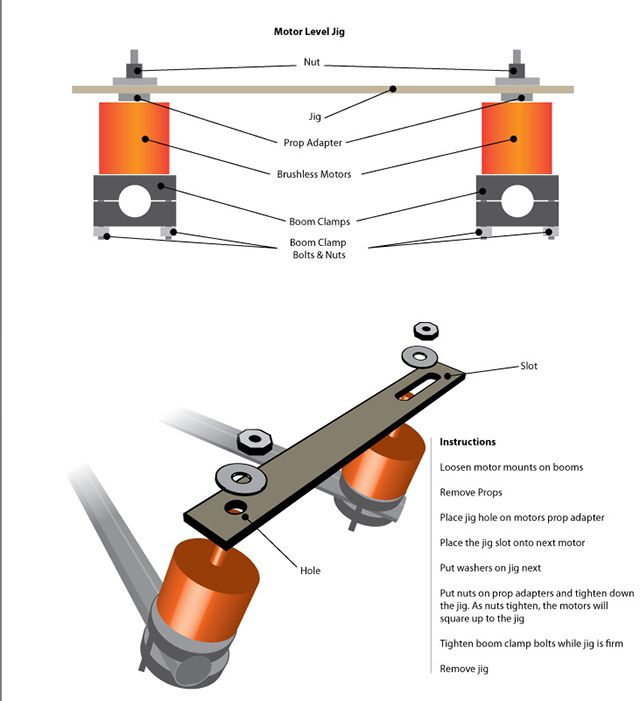

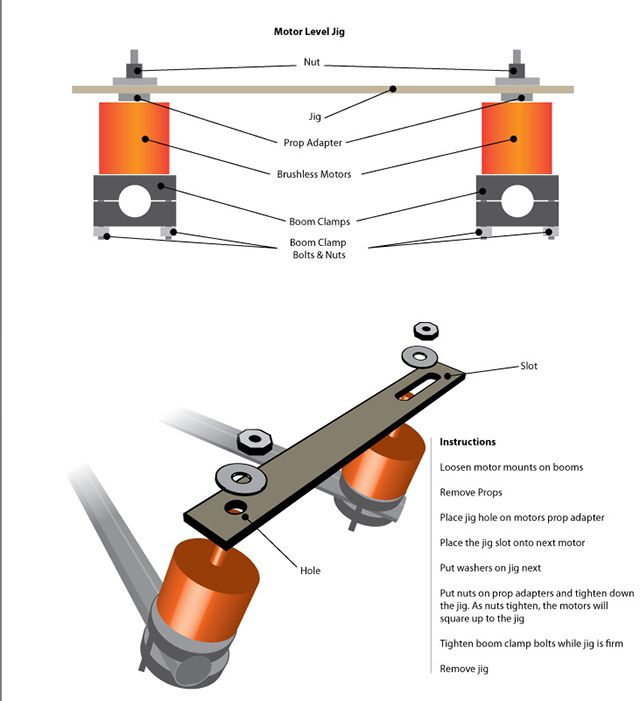

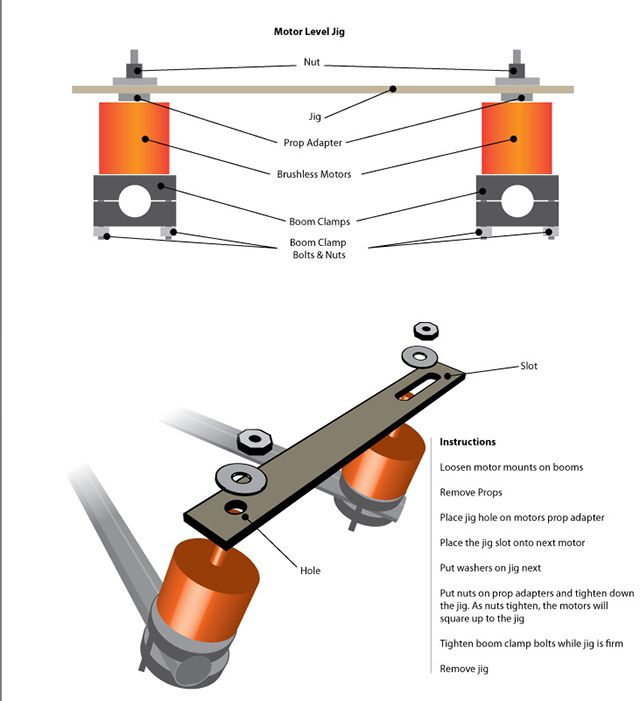

I also found this to try out

- leopold1

- Posts: 311

- Joined: Tue Jul 31, 2012 11:43 pm

- Location: Belgium

Re: Best way to level motors and motor mounts

Nice! Best idea I've seen yet, and adheres well to the KISS principle.

-Max

-Max

- Max

- Posts: 2814

- Joined: Mon Aug 13, 2012 9:45 pm

- Location: Near Ithaca, NY, USA

- chschmid

- Posts: 1800

- Joined: Wed Jul 11, 2012 7:41 pm

- Location: Herrliberg, Switzerland

Re: Best way to level motors and motor mounts

Thats also a good alternative but the holes need to be in the exact position. Preferably with a cheap solution.

- leopold1

- Posts: 311

- Joined: Tue Jul 31, 2012 11:43 pm

- Location: Belgium

Re: Best way to level motors and motor mounts

On mine with round booms, I place the copter upside down on a flat surface (my bench) so it was resting on the ends of the motor shafts. Then I ran a small machinist square all around the edge of the motor rotors and adjusted till they were perpendicular to the bench.

This assumes the shafts are of identical length

This assumes the shafts are of identical length

- GoFaster

- Posts: 355

- Joined: Tue Jul 03, 2012 1:20 pm

- Location: Connecticut, USA

Re: Best way to level motors and motor mounts

Steve

Kisssys

Kisssys

- Kisssys

- Posts: 1340

- Joined: Sat Jun 23, 2012 9:23 pm

Re: Best way to level motors and motor mounts

I like the cups idea, but does it work to ensure motors are parallel on a coax? Probably just the angle of the photo, but in that last picture the motor mount plates don't look parallel to each other. In the past I've used a caliper to measure the distance between the plates at each corner... very tedious but a decent way to check.

-Max

-Max

- Max

- Posts: 2814

- Joined: Mon Aug 13, 2012 9:45 pm

- Location: Near Ithaca, NY, USA

Re: Best way to level motors and motor mounts

Hi Max it is both, the angle the photo was taken and i only loosened one side of the clamps to quickly adjust the mount to the cup, for the sake of taking a picture and showing it ! The curcial parts after having them aligned is tightening the scewrs of the mount and clamps.

Thanks

Boris

Thanks

Boris

- boriss

- Posts: 204

- Joined: Wed Aug 08, 2012 7:26 pm

23 posts

• Page 2 of 3 • 1, 2, 3

Who is online

Users browsing this forum: No registered users and 36 guests